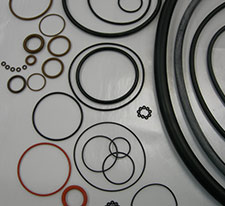

O-RING GASKETS

Ontario Gasket Inc. has been a world leader in gasket fabrication for decades and applies state-of-the-art engineering to produce the highest quality O-ring gaskets in accordance to client specifications. O-ring gaskets from Ontario Gasket Inc. are designed and manufactured using the best selection of materials and precisely sized to guarantee exact tolerance and exceptional performance. The most popular material used in O-ring production is elastomer, which is essentially rubber. The elastomeric material is moulded in one piece to ensure a seamless seal. Silicone glue is also used to join lengths in producing O-rings gaskets. The rubber contains additives that will give it the specific qualities needed to successfully perform in the different environments that the O-ring gasket is applied. The three main requirements of quality O-ring gaskets are performance in high temperatures, chemical resistance and the ability to withstand high pressure.

O-ring gaskets for both static and dynamic applications are available in a number of sizes and designs which can be made according to custom specifications that clients require. The most common characteristics that Ontario Gasket Inc. will strive to achieve with the O-ring gaskets produced are compression set and deformation resistance, resilience, elongation and tear strength, heating aging resistance among others. The commonly used rubber materials include Viton, HNBR, Buna, FSI, Silicone, EPDM, and Kalrez. Others materials sometime utilized include PTFE, NEO and AFL.

Call Ontario Gasket Inc. today and order quick-turn O-ring gaskets for the exact specifications you require and at the most reasonable price quote. Our gaskets achieve exceptional sealing in almost any environment or application.