Ontario Gasket fabricates the bulk of its gaskets from rubber. Rubber in both natural and synthetic form has been the material of choice for the manufacturers of sealing materials due to its uncanny ability to assume their original shape and state after the application of a depressing and deforming force. This attribute is also directly related to its tensile strength. Our professional technicians can help guide customers through the many choices they have as to the best rubber gasket material for their gasket application. Heat accumulates and destroys rubber irreversibly which is why rubber is best suited for low temperature applications. Rubber material is best applied for gaskets which are intended to operate in the middle temperature range so that the shape and functionality of the rubber gasket can be maintained.

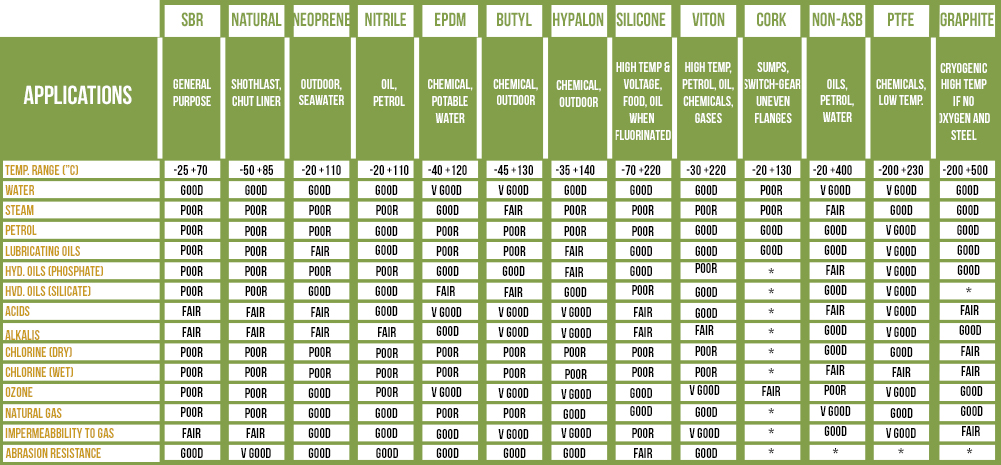

There are many types of rubber gasket material each with different characteristics. The major commercial type of rubber material is SBR, also called red rubber. There are a myriad of other rubber types such as neoprene, nitrile rubber, butyl rubber, EPMD, EP rubber, natural rubber, Hypalon rubber, fluorocarbon, silicon, perfluoroelastomer and aflas. Each material suits different circumstances such as temperature, chemicals and hydrocarbons, abrasion, UV light exposure; and characteristics like compression set, flange load, tensile strength and aging. Often fillers and additives are added to achieve these properties. Ontario Gasket stocks all rubber materials allowing for faster turnaround times in production of gaskets. The experienced team at Ontario Gasket will work with you to ensure that the proper rubber gasket material will be used for your gaskets.